Case Studies

TPM Age: Tokyo Metropolitan Sewerage Service Corp. Kasai Sludge Plant

Use TPM to Become Cake-Makers and Kiln Operators!?

Location: Edogawa Ward, Tokyo

Location: Edogawa Ward, Tokyo

Workforce: 59

Commenced Operations: 1999

Areas Covered: Katsushika and Edogawa Wards

Type of Operation: Sewer Sludge Treatment

Tokyo Metropolitan Sewerage Service Corporation's Kasai Sludge Plant hygienically treats sewer sludge by passing it through the three main process steps of concentration, dewatering and incineration. It introduced TPM in 2007 with the aim of shedding its undesirable image as a place that was dirty, smelly and unpleasant to work in. Then, this year it became the first site in Japan to be awarded the TPM Challenge Prize for sewerage operations management! The plant's catchphrase is 'Cake-Makers and Kiln Operators', but what on earth does that mean...?

Gathering the Raw Ingredients for Cake ーUnit 9ー

The Unit 9 (Focused Improvement) team, whose powerful slogan is 'When it Comes to Kaizen, Leave it to Us!' Front row from left are Yukio Ishibashi, Ken'ichi Sudo, Noriyuki Aihara and Ryo Saito; back row from left are Hiroshi Ido, Toshio Obinata, Yoichi Mitsugi, Kiyotoshi Takeuchi and Kazuyuki Sawada.

This is the scum separator, which recovers the scum (contaminants) by separating it from the dirty water using a rotating-drum-type screen. There were big problems with this process, as contaminants were not being effectively discharged and were building up inside the machine. The scraper that was supposed to scrape off the contaminants adhering to the drum was improved by changing it...

and then by combining the two. This greatly reduced the buildup of contaminants inside the machine and the clogging of the drum discs.

Leave the Kiln to Us! ーSuper Angelsー

The Super Angels maintenance team (Planned Maintenance), a combination of youth and experience, looks after the sludge incinerator - in other words, they are 'kiln operators' who fire the dewatered cakes of sludge. Front row from left are Hajime Tsurue, Hiroshi Kanasawa, Masato Harada, Hideki Kawasoe, Kazunori Kizu, Nishigori Masatsugu and Nobuaki Seki; back row from left are Yasunori Iibachi, Takeo Sakurada, Tetsuya Tanigami and Satoshi Kakizaki.

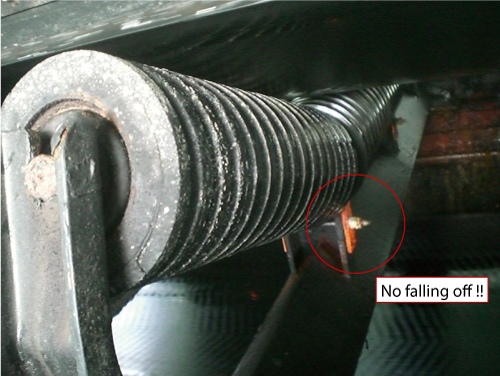

The rollers on the conveyor that carries the contaminants to the incinerator were often knocked off by the shock of the contaminants falling down.

So the team made a fixture to keep the rollers in place. No rollers fall off now!

So the team made a fixture to keep the rollers in place. No rollers fall off now!

They also made the rollers (above) and the chain (right) completely visible.

Making the Dewatered Cake Dough ーChallenge Aー

The cheeky operators of the Challenge A (Autonomous Maintenance) team. Front row from left are Hidefumi Koizumi, Kenji Namiki, Shigeru Kaneko and Shigeo Kaneda; back row from left are Fujio Ikeda, Hiroyuki Kobayashi, Taizo Hayashi and Yutaka Suzuki.

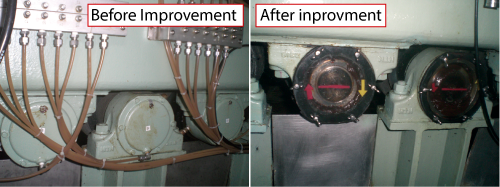

Before Improvement

The dewaterer - the process for making the so-called 'cake dough'. The rollers often fell out of their bearings, and...

The covers had to be taken off each time the machine was restored or checked.

The covers had to be taken off each time the machine was restored or checked.

After Improvement

After Improvement

So the team installed transparent acrylic covers to make the interior of the machine visible, drastically shortening the inspection time.

Sludge Treatment Simulations in the Training Area

This training area set up in a corner of the sludge treatment building's basement is equipped with a variety of model equipment. The transparent apparatus used to simulate the sludge treatment process is particularly effective for training newcomers, as it enables them to understand the process perfectly in a short time.

The TPM committee members who helped with this article. Front row from left are Noriyuki Kitano, Yoshinori Tabata, Toshifumi Uekihara (Site Manager), Yasunori Iibachi and Kazuyuki Sawada (Deputy Manager); back row from left are Takeo Sakurada, Kenji Mizoe, Tetsuro Ichinoma and Youichi Akune.

Services

by over 100 TPM Consultants with average of 20 years TPM experience, and covering over 40 countries.

Active Areas

Our support reaches to Five Major Continents.