Case Studies

TPM Age: J-Oil Mills, Inc, Yokohama

Starting from the site to become Kachi (Winner & Value) Group

Location: Tsurumi-ku, Yokohama City, Kanagawa

Area:48000m2

Employees:214 (as of Mar 2010)

Established:1938

Main Product: Edible Oil for Family and Wholesale,Cooking Oil, Sesame-seed Oil, Olive Oil, Canola Oil

J-Oil Mills, Yokohama launched TPM in April 2005, won TPM Award Category A in 2009, and has developed TPM as Part II activity. They keep the existing activities in shape and expanded them, at the same time, have merged Development Pillar and Planned Maintenance into one pillar called Strategic Maintenance. They have prioritized this pillar and strengthened Office TPM to pursue Kachigumi (Kachi has the double meanings: one is value or value added and the other is win. Gumi means team.) as one of the top management policies.

Lead Racers among the Circles

3K Circle

Circle name is consciously chosen from notorious origin to eliminate 3K (Kitsui = Demeaning, Kitanai = Dirty, and Kiken = Dangerous) workplace. As you can see from the pictures, they have put lots of time and energy for Initial Clean-up. Through efforts in a few months, they have totally swept away 3Ks in the workplace. From left, Takashi Nakajima, Meishi Matsumoto and Shinichi Noda.

Circle name is consciously chosen from notorious origin to eliminate 3K (Kitsui = Demeaning, Kitanai = Dirty, and Kiken = Dangerous) workplace. As you can see from the pictures, they have put lots of time and energy for Initial Clean-up. Through efforts in a few months, they have totally swept away 3Ks in the workplace. From left, Takashi Nakajima, Meishi Matsumoto and Shinichi Noda.

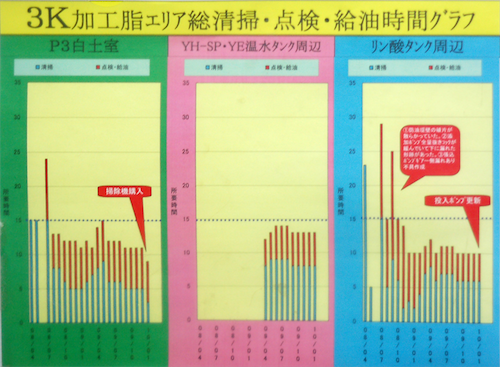

The graphs are shown the time reduction of Cleaning, Check-ups and Lubrication. "After Kaizen, next is Sustain" is the motto of this circle. They are moving to another area.

The graphs are shown the time reduction of Cleaning, Check-ups and Lubrication. "After Kaizen, next is Sustain" is the motto of this circle. They are moving to another area.

Keep Playful Mind and Kaizen by Unified power of Circle Members

Team Count Down Circle

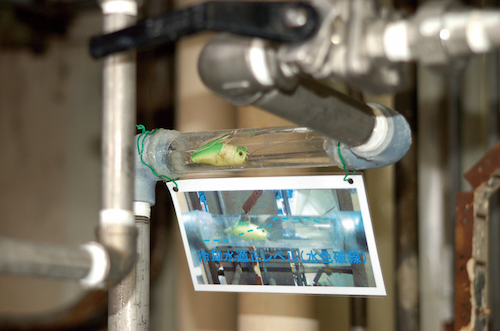

They excel in Karakuri (Low Cost Kaizen by using small and reasonable methods) Kaizen along with conventional TPM activities step by step. They won No1 award for in-factory Karakuri Kaizen contest. You will find the picture of acrylic pipe. "We always have discussions every day." Tomomitsu Kondo, Naoto Matsuda and Masahiko Aizawa.

They excel in Karakuri (Low Cost Kaizen by using small and reasonable methods) Kaizen along with conventional TPM activities step by step. They won No1 award for in-factory Karakuri Kaizen contest. You will find the picture of acrylic pipe. "We always have discussions every day." Tomomitsu Kondo, Naoto Matsuda and Masahiko Aizawa.

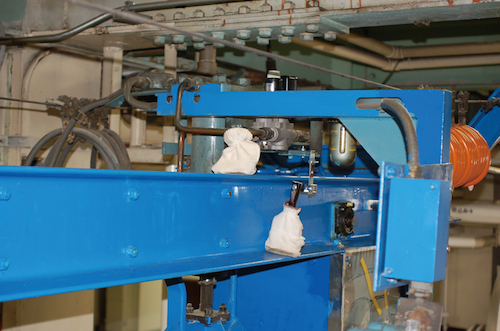

They once cleaned dust by hand wearing cotton work glove. Now they let this automatic cleaning unit to sweep dust away. This Karakuri utilizes motion of vibrating machine. Why cotton work glove? From their experiences, the glove is better than bloom or waste cloth.

They once cleaned dust by hand wearing cotton work glove. Now they let this automatic cleaning unit to sweep dust away. This Karakuri utilizes motion of vibrating machine. Why cotton work glove? From their experiences, the glove is better than bloom or waste cloth.

Once we made it with efforts, show what we did. So they made a news flyer in brilliant colors.

Once we made it with efforts, show what we did. So they made a news flyer in brilliant colors.

This is the award winning Karakuri Kaizen. Part of pipe is replaced with acrylic, and it is a visualization of cooling water flow. A bobber is in it, and indicates proper level of cooling water.

Before this kaizen, it was hard to check the direction of on-off valve. Now, after the kaizen, we can check it from a distance. The indicators are linked with movement angle (90 degree) of valve.

Out and out Visualization. You can see a lot of indicators.

Out and out Visualization. You can see a lot of indicators.

All for OEE improvement, Ban on minor stops

Zoological Park Circle

Circle members, whose target is OEE85%. From left (rear), Hiroshi Aoki, Koichi Kai, Nozomu Miyahara, Sougo Kamiya, and Kazuhiro Ezaki. From left (front), Miyo Ishikawa, Fujiko Sato and Hiroshi Shigematsu.

Line is stopped by clogged cap at shoot. We applied Why-why analysis, and modified width of shoot and air pressure at 0.4MPa, and have achieved Zero stop. This would be at the level of PM Analysis.

Line is stopped by clogged cap at shoot. We applied Why-why analysis, and modified width of shoot and air pressure at 0.4MPa, and have achieved Zero stop. This would be at the level of PM Analysis.

Flashing eyes call attention when too much force is applied to crash the bottle. Never at night.

Flashing eyes call attention when too much force is applied to crash the bottle. Never at night.

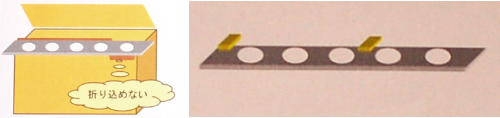

Operators manually assisted to fold 3000 to 4000 cardboard tops at the caser machines. This was too much burden for them, so the guide with small plates was made. This has achieved zero defects of the top folding.

This is TPM Mascot of Yokohama factory, and the name is Gabbie, comes from Italian word Gabbiano, Seagull in English.

Thanks for TPM people at J-Oil Mills, Yokohama

From left, Takashi Kusakabe of Yokohama Pac, Takeshi Osakai of TPM promotion office, and Youichiro Nagatome of the production

From left, Takashi Kusakabe of Yokohama Pac, Takeshi Osakai of TPM promotion office, and Youichiro Nagatome of the production

Services

by over 100 TPM Consultants with average of 20 years TPM experience, and covering over 40 countries.

Active Areas

Our support reaches to Five Major Continents.