News & Tips

4 Nov 2019

TPM Knowledge

Ownership with TPM: My Machine, My Responsibility

You will not be able to eliminate equipment breakdowns if you have a culture of "I make. You fix."

Operators need to upgrade their skills and abilities to protect their equipment and thus foster a sense of "My Machine" to achieve Zero Breakdowns.

Aim for Zero Breakdowns with Autonomous Maintenance

In a workplace without Autonomous Maintenance implementation, abnormalities are not detected as abnormalities, or at all. If the right treatment to eliminate abnormalities is not done, breakdowns and defects occur frequently. With frequent breakdowns and defects, productivity decreases, unscheduled work increases, and in some cases accidents occur. In your workplace, you need to check if breakdowns, caused by lack of inspection and/or lubrication, are left without any treatment.

Autonomous Maintenance activity is purposed on "Protecting My Machine" through daily inspection, lubrication, parts replacement, repair, and early detection of abnormalities.

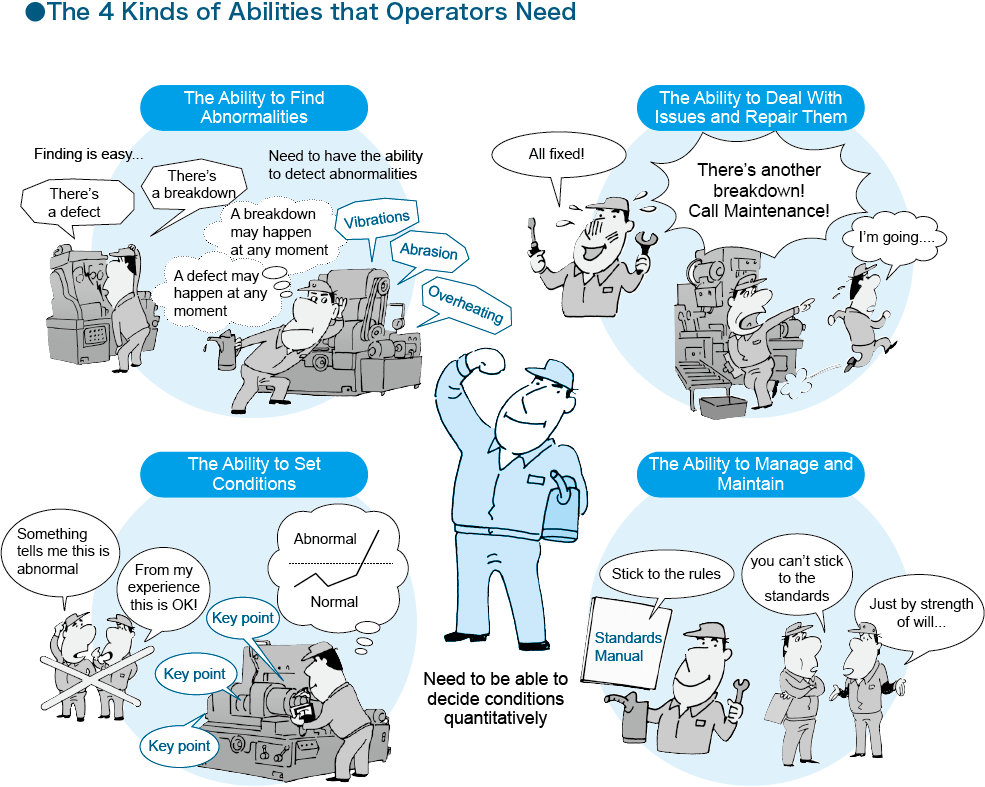

To carry out the right way of Autonomous Maintenance, the following 4 maintenance abilities need to be adhered to in addition to the knowledge required for normal production:

-

Abnormality Detection Ability: Being able to detect abnormalities

-

Treatment/Restoration Ability: Being able to make immediate and correct responses to abnormalities

-

Condition Setting Ability: Being able to judge normal or abnormal with quantitative measurements/standards

-

Sustainment Management Ability: Being able to comply with determined rules

Related News

-

27 Apr 2023

TPM Knowledge

TPM Regla de Oro #09: Este es el punto clave de Mejora Enfocada (Kobetsu Kaizen) en TPM.

-

27 Apr 2023

TPM Knowledge

Regra de Ouro #09 do TPM: Os pontos chaves da "Melhoria Isolada/Melhoria Espec?fica" s?o estes.

-

17 Mar 2023

TPM Knowledge

TPM Reglas de Oro #08:Antes de hacer una mejora (Kaizen), primero se tiene que hacer restauración (Fukuguen) !

Active Areas

Our support reaches to Five Major Continents.